The Boxes Supplier makes rigid packaging that gives perfect protection to products.. Brand identity gets elevated through sleek finishes and customized design options available. Business owners who want to impress customers choose functional packaging solutions daily. Packaging gives companies a way to distinguish themselves from their competition across every region's congested market. Strong packaging is a requirement for jewelry stores, perfume boutiques, and tech companies.

What Makes Rigid Boxes Special?

Rigid boxes work differently than folding cartons or corrugated packaging materials today. Folding cartons feel lightweight and bend easily when touched by customers shopping. Rigid packaging offers sturdy structure that does not collapse under heavy pressure. Compressed paperboard or chipboard creates balance between looks and toughness perfectly everywhere. These boxes are four times thicker than regular cartons in stores. Solid feel makes consumers think about luxury when they touch expensive boxes.

Weight difference between regular boxes and luxury rigid boxes surprises customers immediately. Thick walls resist crushing damage during transport to different countries worldwide. Premium materials cost more money but protect valuable products much better. Glass items, ceramic pieces, and metal jewelry stay safe inside strong boxes. Temperature changes cannot warp or damage these boxes during hot summers. Cold winter weather also cannot crack or break the thick walls.

Different Types of Rigid Boxes

Rigid packaging comes in many styles for different business needs today. Several types of Custom rigid boxes serve different industries and branding goals. Popular types include many design options for various customer requirements.

1. Telescopic Rigid Boxes

Telescopic rigid boxes are the most common designs companies choose regularly. They have separate lid and base parts like traditional shoe boxes everywhere. These boxes give easy access and sturdy protection for products inside. Apparel, electronics, and luxury retail stores use them often for daily sales. Assembly workers can pack products quickly using this simple two-piece design. Storage becomes easier when lids stack on top of bases separately.

2. Hinged Lid Rigid Boxes

Built-in hinges connect the base and lid together in one single piece. These boxes combine style with easy use for customers who shop daily. Jewelry and electronics brands like this design because it opens smoothly always. The packaging stays together and does not break into separate pieces ever. Hinges can be constructed of cloth, paper, or specially formulated synthetic materials. Durable hinges can survive for decades without fracturing or becoming worn.

3. Drawer-Style Rigid Boxes

Drawer boxes work like matchboxes with sliding inner trays that move smoothly. The inner tray slides out easily for unique unboxing experiences customers enjoy. Cosmetics, accessories, and gift sets often use this exciting box style. Customers enjoy the sliding motion when opening their new purchases from stores. Inner trays can have dividers to separate different products or accessories. Soft fabric lining protects delicate items from scratches during sliding motions. Some drawer boxes have multiple trays that stack inside each other. This design works well for jewelry sets with matching pieces.

4. Collapsible Rigid Boxes

Collapsible rigid boxes save storage space when not being used regularly. They fold flat during shipping or storage until companies need them immediately. Assembly happens quickly when workers need to pack products for customers worldwide. Space-saving features reduce warehouse costs for companies with limited storage areas. Flat-packed boxes cost less money to ship to manufacturing facilities everywhere. Setup instructions are simple and workers learn assembly processes very quickly. Strong magnetic strips or snap closures keep assembled boxes closed securely.

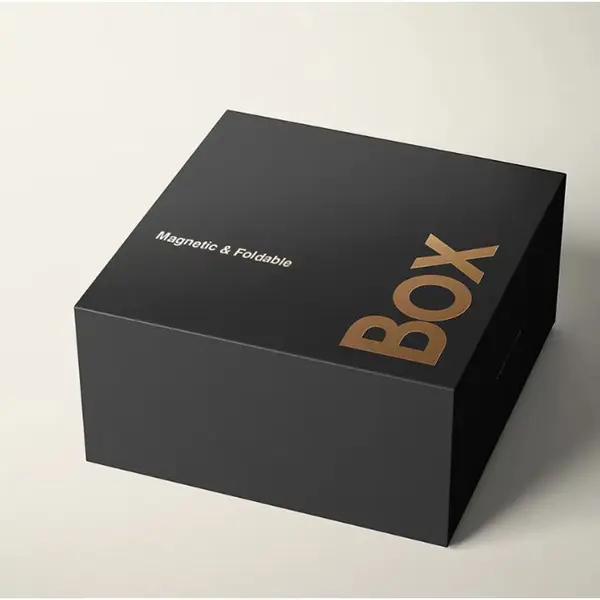

5. Magnetic Rigid Packaging

Magnetic closure boxes create sophisticated unboxing experiences for customers everywhere today. Magnets click together when closing and add premium quality feelings immediately. These boxes work perfectly for luxury fashion, perfumes, and exclusive electronics always. Magnetic rigid packaging stays secure and provides elevated unboxing rituals customers remember forever. The magnetic click sound makes customers feel like they bought something special. Hidden magnets stay invisible but provide strong closing power that lasts. Different magnet strengths work for light products or heavy items perfectly. Some boxes use multiple magnets for extra security and professional appearance.

6. Shoulder and Neck Rigid Boxes

Three-piece boxes have neck pieces placed between base and lid parts carefully. This unique construction gives them expensive appearance that customers notice immediately when shopping. The extra piece makes boxes look more complex and valuable than simple designs. Assembly requires more skill but creates impressive results that justify higher costs. Shoulders provide extra protection for fragile items during shipping and handling processes. Different shoulder heights create various looks for different product types and brands.

7. Round Rigid Boxes

Round or cylindrical rigid boxes offer modern design that stands out everywhere. Food and cosmetic industries use them because they look different from squares. Retail shelves display them well because of their distinctive round shape always. Curved walls provide extra strength against crushing forces during shipping worldwide. Stacking becomes more challenging but creates interesting display patterns in stores. Some round boxes have windows that show products inside without opening.

How Manufacturing Works Differently

Specialized equipment handles thick materials that regular machines cannot process properly. Skilled workers need training to operate complex machinery that creates quality results. Quality control checks happen at every step to ensure perfect boxes.

- Material Preparation Thick paperboard ranges from 36pt to 120pt in thickness measurements exactly. Regular cartons collapse easily, but these boards stay strong always during handling. Durability comes from using compressed materials that resist bending and breaking completely. Different grades of paperboard work for different product weights and shipping distances. Moisture resistance gets added through special treatments that protect against humidity. Some materials include recycled content while maintaining strength and appearance standards.

- Wrapping and Covering Decorative paper or specialty material covers the thick board completely without gaps. Textured paper, leatherette, or fabric create custom magnetic rigid boxes that feel expensive always. Different covering materials change how boxes look and feel to customers completely. Adhesives must bond perfectly to prevent peeling during use and storage. Some coverings include special coatings that resist fingerprints and water damage. Wrapping machines apply even pressure to eliminate bubbles and wrinkles that look unprofessional.

- Assembly Process Machines cut and crease boards with exact measurements every single time. Skilled workers assemble boxes by hand to make sure everything fits perfectly. This careful process makes boxes look flawless when customers receive them at home. Corner joints need precise alignment to create strong connections that last.

- Printing and Finishing Printed rigid boxes can have foil stamping, embossing, spot UV, or special coatings. Matte and gloss lamination options make boxes look professional and attractive always. This finishing process makes them different from basic packaging materials. Digital printing works for small orders while offset printing handles large quantities. Color matching systems ensure consistent results across different production runs worldwide. Drying time between printing steps affects production schedules and delivery dates significantly.

- Special Features Magnetic rigid packaging, ribbon closures, and inserts get added during final assembly steps. These features make boxes easier to use and more attractive for customers. Customer experience improves when boxes have special closing mechanisms and soft protective inserts. Insert materials include foam, velvet, silk, and molded plastic options.

Where Rigid Packaging Gets Used

Common uses include many different product types and business needs worldwide. Insurance claims decrease when products ship in protective packaging that prevents damage. Return rates go down when customers receive undamaged products in attractive boxes. Brand reputation improves when packaging matches product quality and customer expectations consistently.

Jewelry & Watches – Expensive items need luxury rigid boxes to maintain exclusive feelings always.

Electronics – Smartphones, headphones, and gadgets rely on rigid boxes for complete protection during shipping.

Cosmetics & Perfumes – Visual appeal of printed rigid boxes enhances shelf presence dramatically in stores.

Fashion Accessories – Sunglasses, ties, and wallets get packed in custom boxes regularly for sales.

Corporate Gifting – Premium giveaways need sturdy packaging that shows quality and company values.

Food & Beverages – Specialty items like chocolates, wines, and gourmet foods use attractive packaging.

Medical Devices – Sensitive equipment needs protection from moisture, dust, and impact damage.

Why Choose The Boxes Supplier for Rigid Boxes?

The Boxes Supplier understands that packaging tells brand stories to customers effectively every day. Expertise lies in designing and producing custom rigid boxes wholesale that reflect brand values perfectly. Quality materials and advanced printing create boxes that impress customers every single time. Years of experience help solve complex packaging challenges that other companies cannot handle. International shipping capabilities serve customers in many countries around the world reliably. Technical support helps customers choose the right materials and features for products.

Customization Excellence – Unlimited options in size, shape, color, and finish choices available.

Premium Materials – Textured paper to specialty laminates, only finest materials get used always.

Advanced Printing – Printed rigid boxes come with bright graphics and luxury finishes that shine.

Strength Guaranteed – Whether magnetic rigid packaging or collapsible styles, boxes stay strong during shipping.

Smart Pricing – Despite luxury appeal, cost-effective solutions fit different budgets perfectly without compromise.

Fast Delivery – Production schedules accommodate urgent orders and seasonal demands efficiently.

Design Support – Creative teams help develop packaging concepts that match brand identities exactly.

Track record in delivering luxury rigid boxes makes this company trusted worldwide by brands. Partnerships provide packaging that stands out in markets and impresses customers consistently. Before approval for shipment, every box undergoes quality control to ascertain that certain standards are achieved. Customers’ testimonials indicate that packaging solutions positively impacts sales and brand awareness. Repeat customers highlight that expectations are met and long-term relationships are established.

How Rigid Packaging Affects Brand Success

Premium packaging can increase how much customers think products are worth immediately. Customers who get watches in simple cartons think they are ordinary products. The same watches in elegant custom rigid boxes feel more valuable and expensive immediately. Psychologists agree that packaging captures customers’ attention and greatly impacts their decision to buy every day.

Sustainable Rigid Packaging Options

Environmental responsibility has become important in packaging choices for many companies today. Some brands think rigid boxes cannot be eco-friendly, but that thinking is completely wrong. The Boxes Supplier offers eco-conscious solutions using recyclable paperboards and environmentally safe inks. Biodegradable laminates help companies stay environmentally responsible while maintaining brand prestige always.Sustainable printed rigid boxes showcase how companies need not sacrifice the environment in the pursuit of success.

Getting Started with Rigid Packaging

The Boxes Supplier provides consultation services to help companies make smart packaging choices. Design teams work with businesses to create packaging that fits perfectly every time. From concept development to final production, support continues throughout the entire process consistently. Sample production allows testing before committing to large orders that cost money. Feedback incorporation ensures final products meet expectations and brand standards exactly. Project management keeps orders on schedule and within budget limits always.

Rigid box packaging has become the norm for premium brands in a number of different sectors. The combination of strength and elegance along with a myriad of customization choices has made them a necessity in highly competitive markets. Be it custom rigid boxes, highly luxury rigid boxes, or innovative custom magnetic rigid boxes, The Boxes Supplier provides packaging that shows sophistication and strength.