-

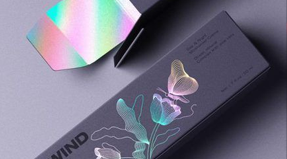

Premium Packaging

Shop All Product

Get Help With Expert Guidance

Need help finding the perfect packaging? Contact us now for a free consultation with a trained packaging specialist.

Call Us Toll Free

+15716226876 - Rigid Boxes

- Luxury Boxes

- Neon Signs

- Signages